Engineering

Our Advanced Machinery

State-of-the-Art Equipments:

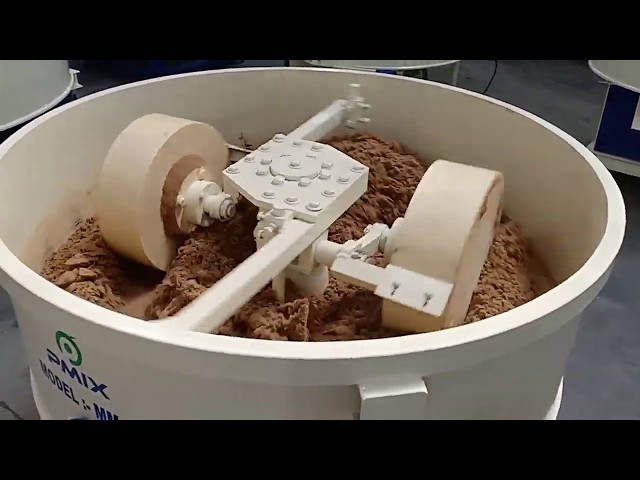

At North East Sillimanite LLP, we utilize the latest technology to ensure the best quality of refractory products. Our advanced machinery includes:

For Crushing, Grinding, and Grading

We have a Jaw Crusher, Impact Mill, Vibrating Screen, Magnetic Separator, and Silo to use for crushing, grinding, grading, magnetic material separation, and storage of batch-making materials.

A Ball Mill and Pulverizer are used to get the fine material into powder.

For Molding and Pressing:

We have different types and capacities of press from 120 T to 400 T, to produce the bricks by pressing (i.e. Hydraulic Press, FSP, Automatic Press, and Semi-Automatic Press), Vibro table for Casting and all necessary equipment for moulding in the green production area to get consistent properties as per the product applications.

For Drying & Firing

Drying is required to initially remove the physically bonded water of the green product from ambient temperature to 120 °C.

High-temperature kilns are used to fire the products with an advanced Firing system for optimal strength and durability.

Tunnel Kiln

Trolley Cars

Tunnel Dryer

Machinery Benefits:

- Enhances product quality

- Increases production efficiency

- Reduces waste and environmental impact